Revolutionizing Manufacturing: The Role of Generative AI

Revolutionizing Manufacturing: The Role of Generative AI

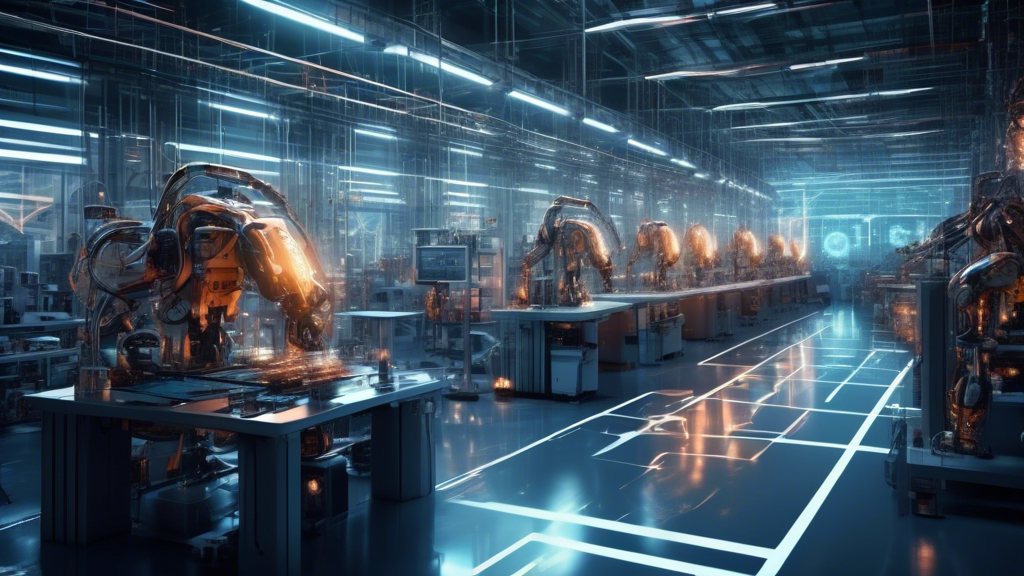

In the rapidly evolving landscape of modern manufacturing, the integration of artificial intelligence (AI) technologies has been nothing short of transformative. Among the most groundbreaking advancements is the advent of Generative AI, a subset of AI focused on creating new content, designs, or data that was not explicitly programmed into it. This novel approach has the potential to revolutionize manufacturing processes, from product design to production, in unprecedented ways.

Understanding Generative AI

At its core, Generative AI encompasses algorithms that enable machines to leverage vast amounts of data to generate original outputs. Unlike traditional AI, which typically analyzes and learns from data to make predictions or carry out tasks, Generative AI takes this a step further by producing new, unseen before results based on learned data patterns. This could range from generating new product designs to optimizing manufacturing workflows.

The Impact on Product Design and Prototyping

One of the most notable impacts of Generative AI in manufacturing is in the area of product design and prototyping. By harnessing generative algorithms, companies can explore a vastly expanded landscape of design possibilities. This technology can iterate through countless design variations, refining and optimizing based on specific criteria such as durability, cost, and material use. The result is a greatly accelerated design process that can lead to more innovative and efficient products entering the market more quickly than ever before.

Streamlining Manufacturing Processes

Beyond design, Generative AI has significant implications for the actual manufacturing process. It can optimize production lines by predicting and adjusting for potential inefficiencies, thus ensuring smoother operations. Additionally, it can aid in the development of custom manufacturing tools and machinery, tailor-made for specific tasks, further enhancing productivity. Generative AI’s ability to simulate and model manufacturing scenarios also means that potential issues can be identified and addressed before they cause real-world problems, saving time and resources.

Customization on Demand

Perhaps one of the most exciting prospects of Generative AI in manufacturing is its ability to facilitate highly personalized products at scale. Traditionally, mass customization has been challenging and costly for manufacturers, limited by the complexities of altering production lines and designs for individual preferences. However, with generative models, creating unique product variations based on customer specifications becomes significantly more feasible and efficient, potentially reshaping consumer expectations around personalized products.

Challenges and Considerations

While the potential of Generative AI in manufacturing is immense, it’s not without its challenges. The integration of such advanced AI systems requires significant investment in technology and training, as well as a cultural shift within organizations towards more agile and innovative practices. Additionally, there are ethical considerations around the use of AI-generated designs, including intellectual property rights and the potential for job displacement.

Looking Ahead

The role of Generative AI in manufacturing is expected to grow as technology continues to advance and more industries recognize its potential. By enabling faster innovation, enhanced customization, and greater efficiency, Generative AI is poised to redefine what’s possible in manufacturing. As companies navigate the challenges and opportunities this technology presents, those who can successfully integrate Generative AI into their operations are likely to emerge as leaders in the next evolution of the manufacturing sector.

editor's pick

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua